The five main commodity resins are polyethylene (LDPE, LLDPE, HDPE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and polyethylene terephthalate (PET). Key applications range from flexible and rigid food and non-food packaging, to a broad range of consumer goods products, agricultural and industrial products, automotive, and construction, including pipes.

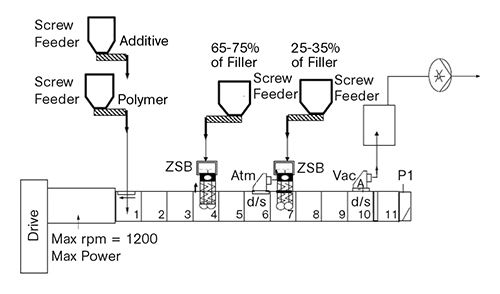

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Commodity Resins: Essential Reading

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Density & Molecular Weight in Polyethylene

This so-called 'commodity' material is actually quite complex, making selecting the right type a challenge.

Tracing the History of Polymeric Materials: Commodity Resins

How the ‘Big 4’ commodity materials — PE, PP, PS, PVC — came to be.

Tracing the History of Polymeric Materials: Celluloid & Film Stock

In this series we delve into a discerning look back into the history of our industry and how we all got here.

FAQ: Commodity Resins

Polyethylene is considered a “commodity” material, a designation that gives the impression that not much thought needs to go into picking the correct grade of material. But PE can be remarkably complicated simply because it is the only polymer that is available across a wide range of densities.