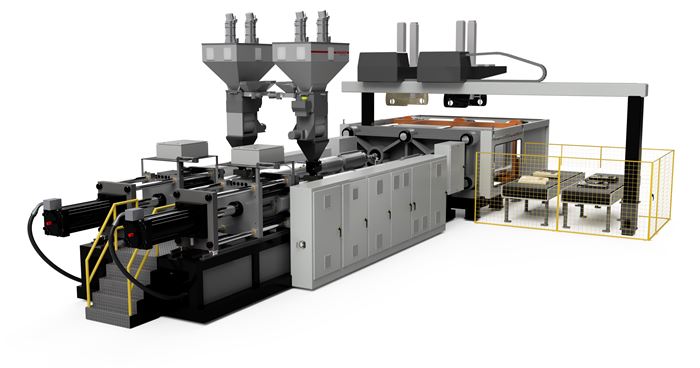

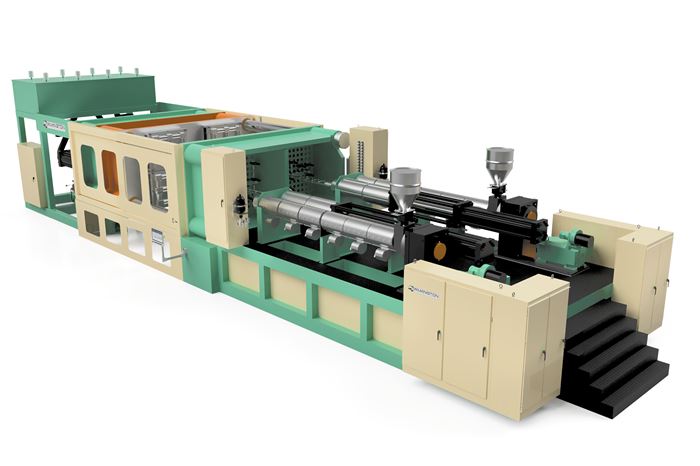

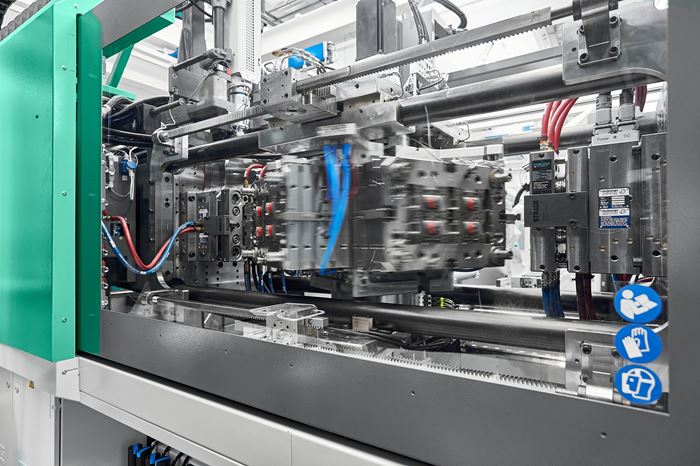

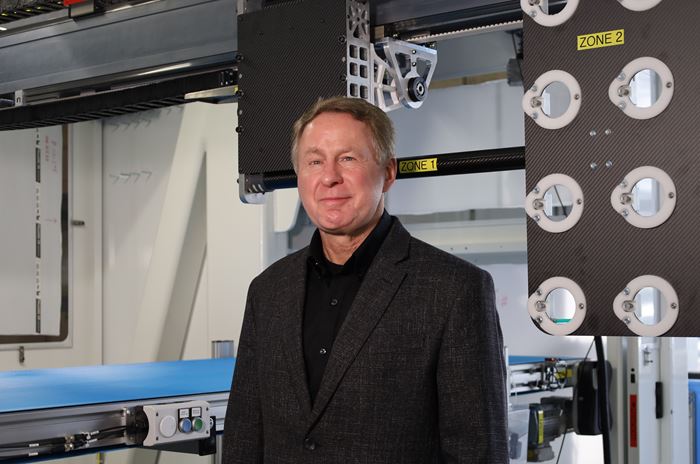

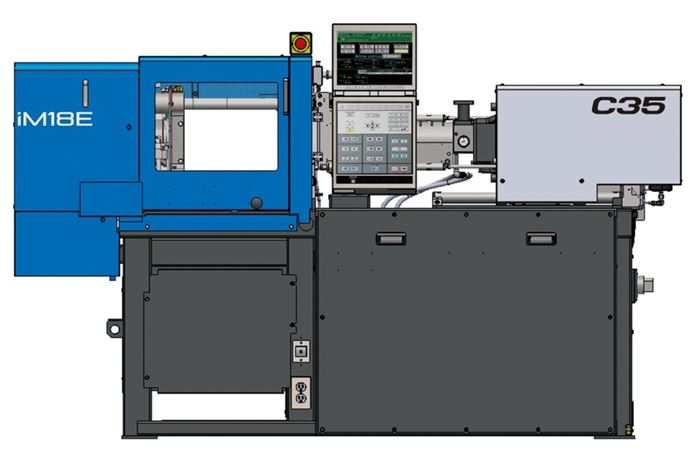

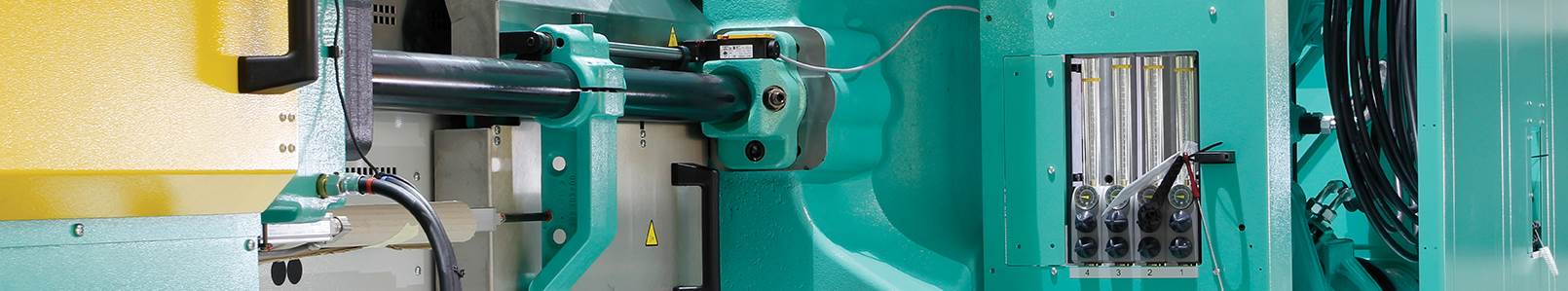

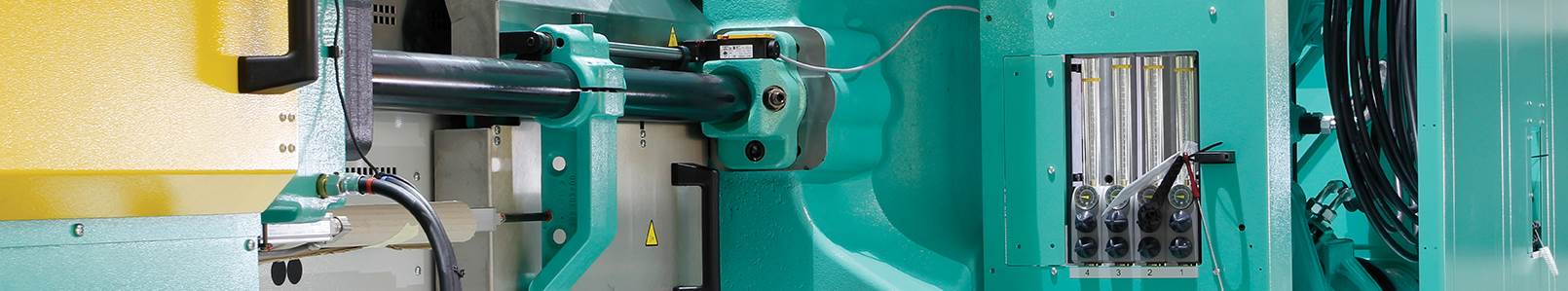

In injection molding, material is fed through a hopper into a barrel where a reciprocating screw mixes and melts the material then injects it into a mold.

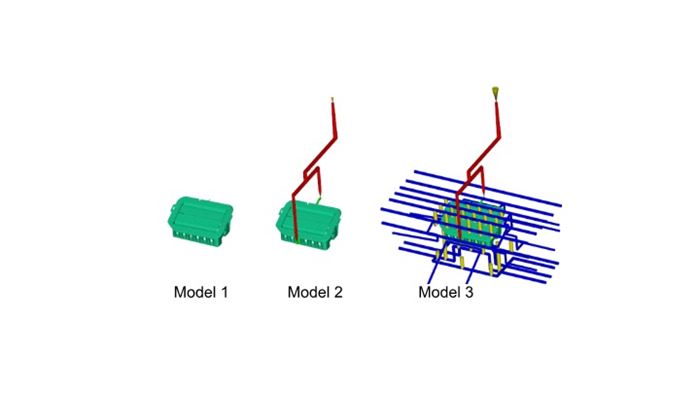

How to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

Injection Molding: Essential Reading

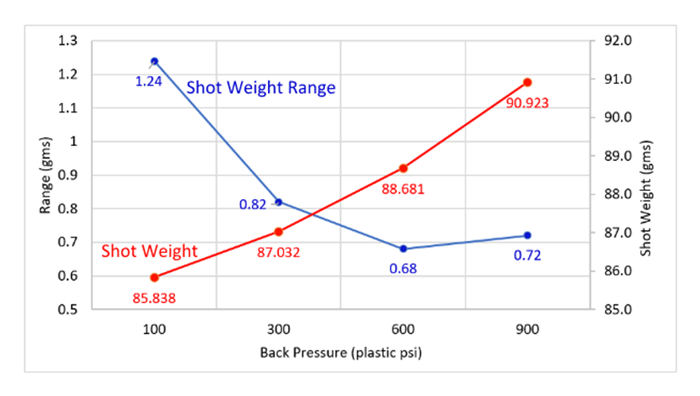

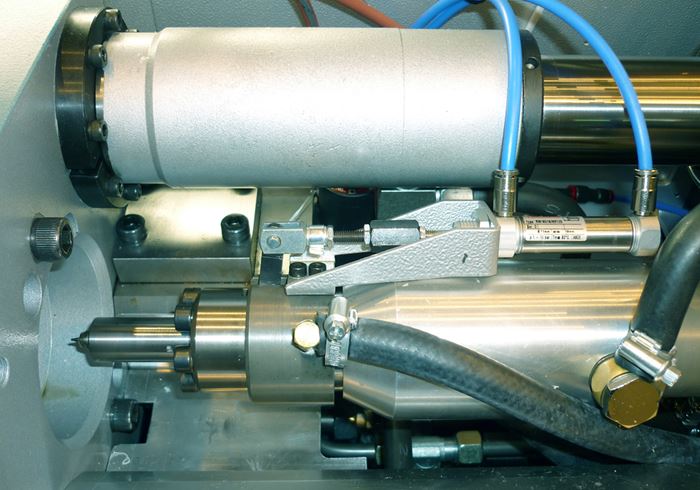

How Backpressure Optimization Affects Melt Preparation

Backpressure is often the least understood of the settings in an injection molding process, even though it can play a significant role in the final quality of the part. Let’s start with understanding what backpressure is and then learn how to optimize it for a given mold.

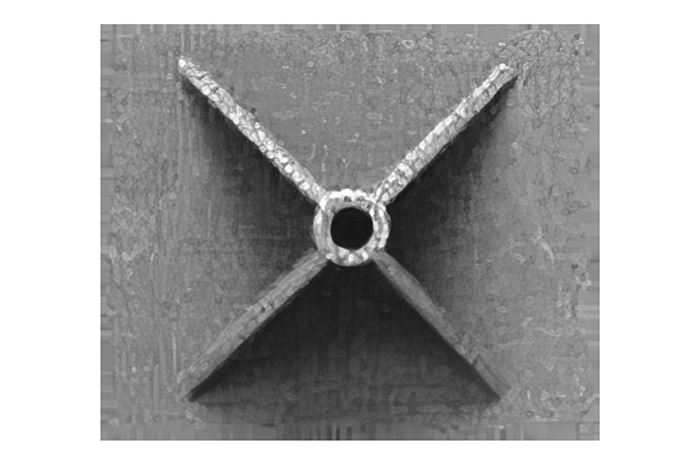

How to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

21 Tips to Slash Energy Costs in Molding

This checklist can provide injection molders a good starting point on the path to reduced energy consumption and can generate some money savings on that journey.

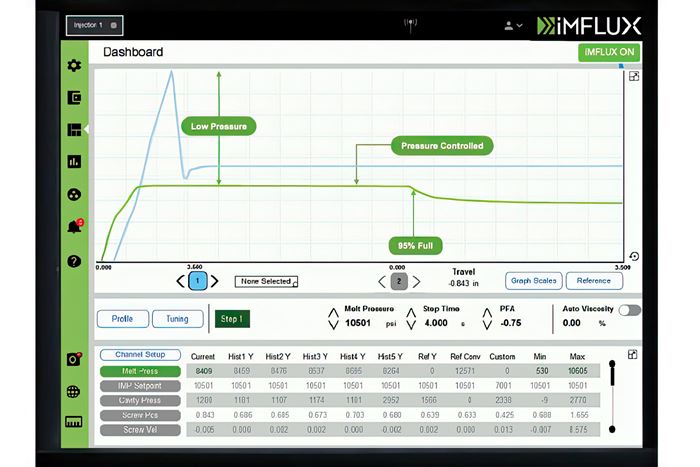

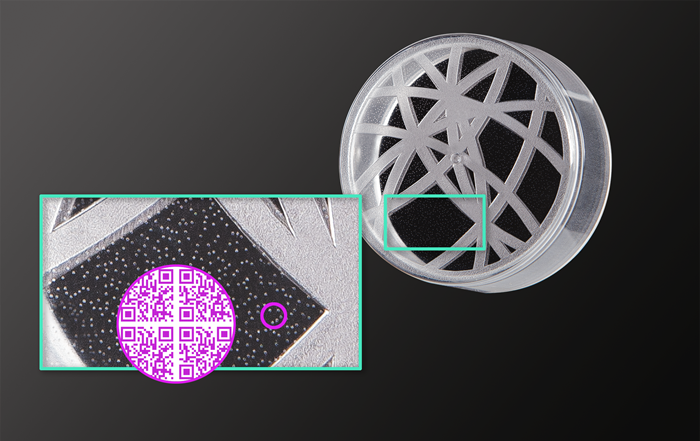

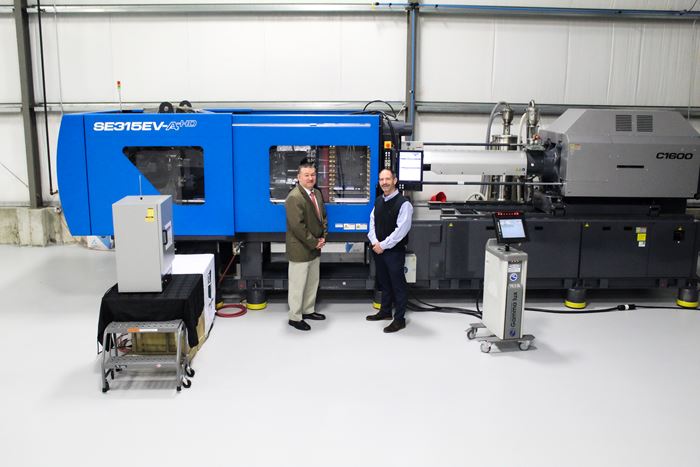

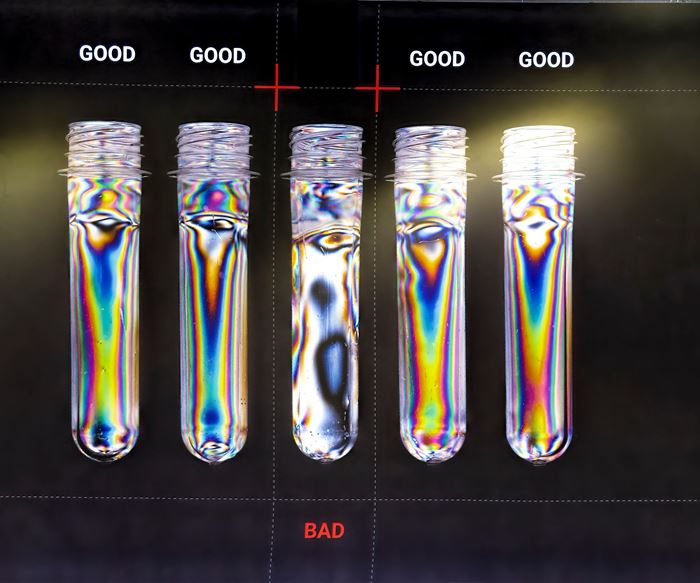

Use Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

How Important is Minimizing Residence Time in Injection Molding?

Does a focus on the concept of “minimum residence time” distract attention from areas of injection molding that have more of a direct impact on melt quality?

FAQ: Injection Molding

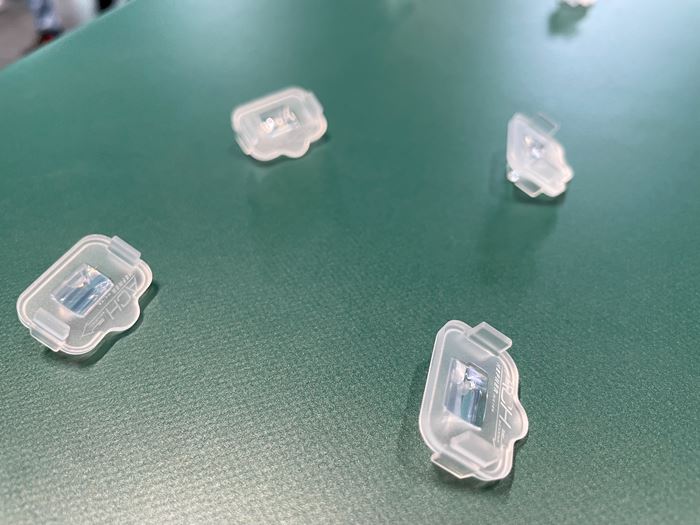

Plastic injection molding is a cyclical manufacturing process that allows for cost-efficient production of a mass number of identical parts made from either thermoplastic or thermoset materials.

Cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. A consistent cushion will create consistent part dimensions.

It is important to determine which type of bubble your part has, and what the root cause might be. Determining bubble type will allow you to pinpoint the source and determine your next course of action to eliminate the problem.

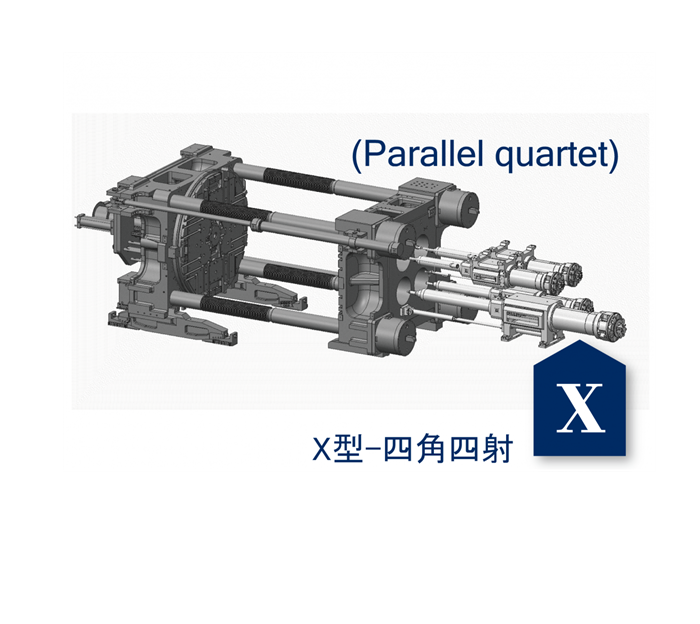

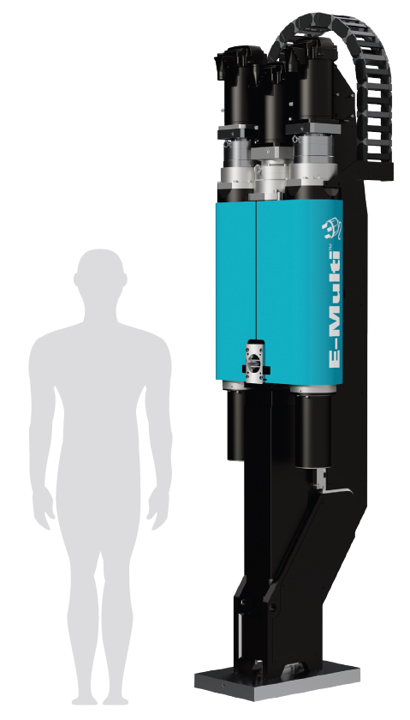

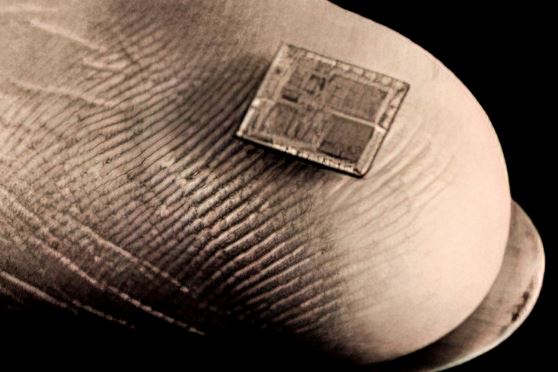

Most molders are still relying on “general-purpose” screw designs that go back 30 years. With all of the technical improvements that have been made on machines over that time, nothing has been done to improve melt uniformity. We still use “general-purpose” (GP) screws, which well-known screw designer Bob Dray wisely has called “no-purpose” screws. That is they do not melt plastic uniformly. Processing with a uniformly melted plastic would seem like a high priority, but it has seen little if any attention.

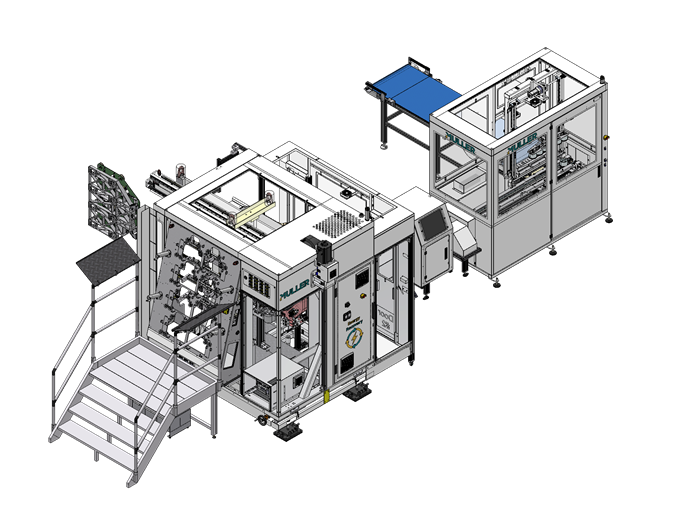

Injection Molding Suppliers

Narrow by Injection Molding Category

- Injection Molding Machines

- Accumulators (Melt)

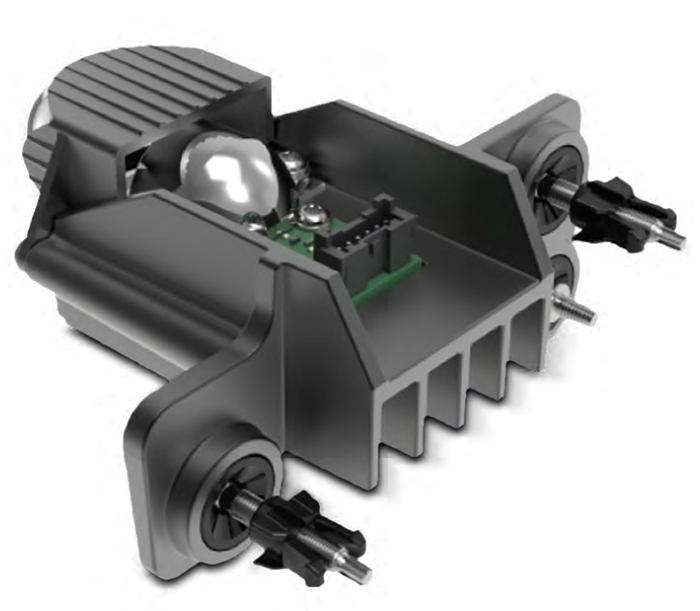

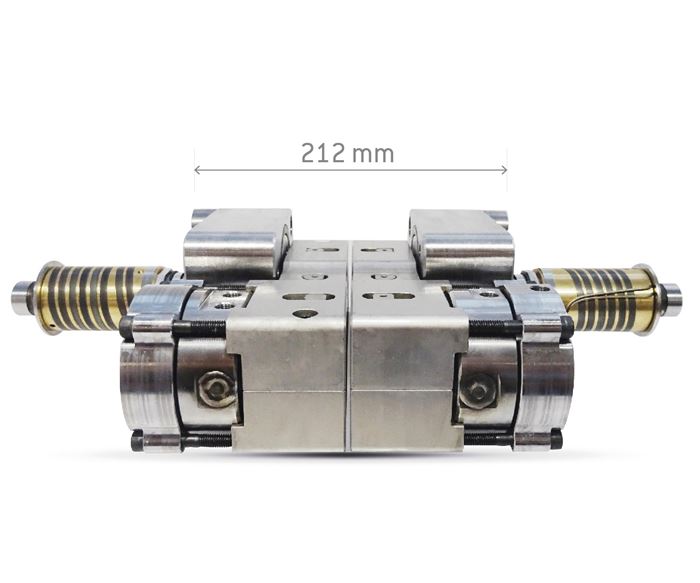

- Injection Molding Non-return Valves

- Injection Molding Nozzles

- Inserts

- Platens

- Thermoformers

- Trimmers, Deflashers for Blow Molding

- Parison Programmers

- Spray Coating Systems (for Bottles)

- Dip-Blow or Compression-blow Molding Machines

- Extrusion Blow Molding Machines

- Stretch-Blow Molding Machines

- Injection Blow Molding Machines

- Pre-expanders, Polystyrene Bead

- Presses, Polystyrene Bead

- Structural Foam Machines (for Thermoplastics)

- Injection Blow Molds

- Injection Molds

- Mold Components

- Compression/Transfer Molds

- Cutting, Stamping, Trimming Dies

- Foam Molds

- Compression/Transfer Presses

- Hot Runner Components

- Mold Evacuation Systems

- Mold Making and Repair Equipment

- Mold/Die Management Systems

- Prototype Molds

- Quick-mold-change Equipment

- Rotational Molding Machines

- Thermoforming Molds

- Rotational Molds

- Mold-cleaning and Maintenance Chemicals

- Mold Grease

- Mold Steels

- Nonferrous Metals for Molds

- Nonmetallic Tooling Materials