Temperature control in plastics processing includes mold temperature control, chillers, cooling towers, and heat exchangers.

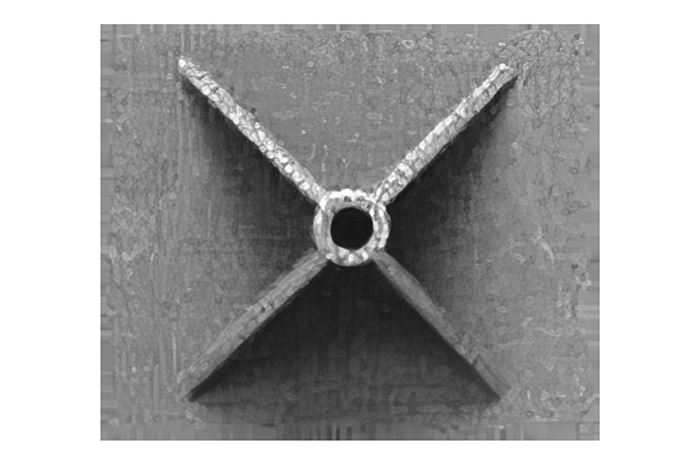

How to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Heating & Cooling: Essential Reading

Troubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

Cooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Cooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

How to Know the True Value of Conformally Cooled Injection Molds

What’s the return on investing in a new mold with conformal cooling to boost productivity? Will it pay for itself? How soon? Here’s a case study on how to answer those questions.

FAQ: Heating & Cooling

Are Conformally Cooled Injection Molds Worth It?

When evaluating cost-reduction projects in injection molding, the discussion typically centers around cycle-time reduction and the cost to implement the change. This article explores the true value of conformally cooled injection mold in a very specific case. That case is when the molder can sell more product than it can make on a 24/7 basis.

How to Fix Mold Temperature Control?

Mold-temperature control is just one of many process elements that can affect the quality of an injection molded part. In a perfect world, anyone running a particular mold would know what the mold designer set as the ideal temperature and flow rate for the cooling water. In reality, operators and setup personnel don’t always know these settings and/or something changes so that it is necessary to re-establish them by trial and error.

How to Improve The Cooling Performance Of Molds?

The first law of thermodynamics states that energy cannot be created or destroyed, but only transferred from one place to another. If you think of an injection mold as a closed thermodynamic system, you can account for the energy entering and leaving the system. A shot of molten plastic injected into a mold is the energy input, and energy leaves by various mechanisms. Some of the energy (heat) is carried away in the ejected parts and some is removed by the cooling system. It is less obvious, but some energy will also go into the surrounding environment when a mold is heated substantially above room temperature.