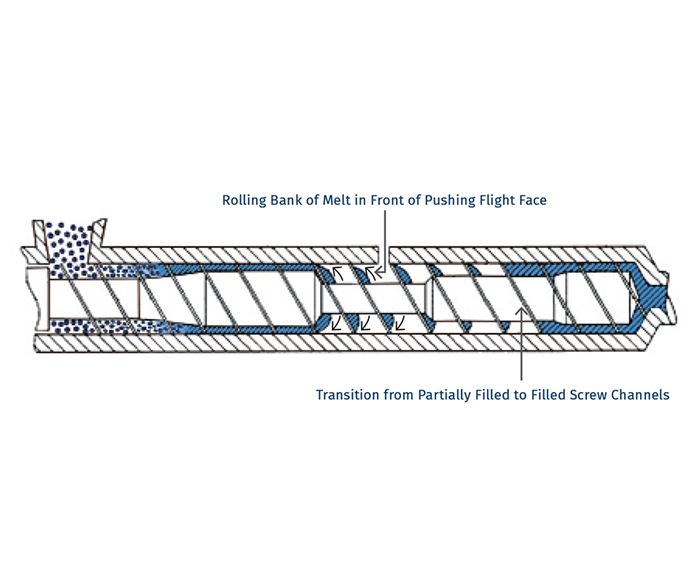

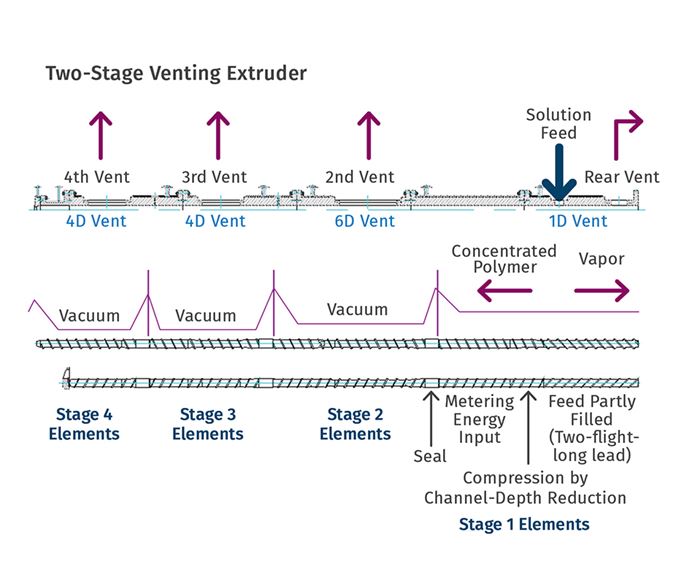

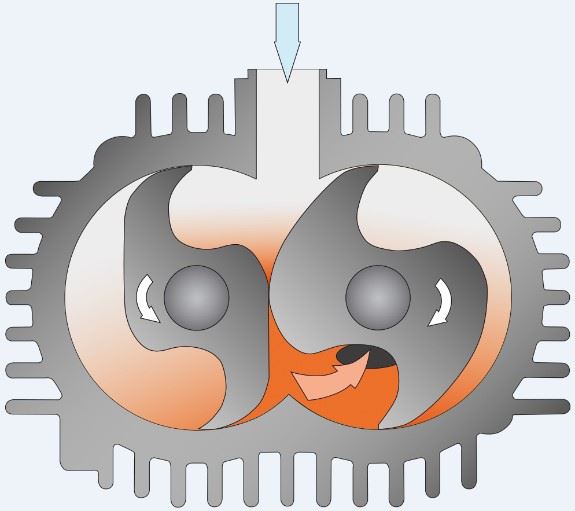

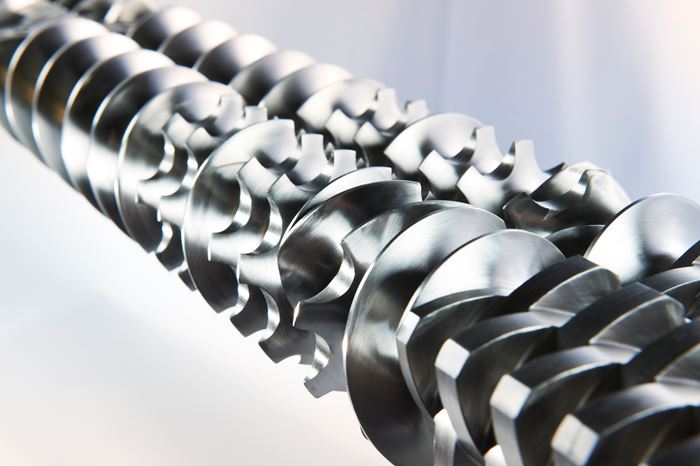

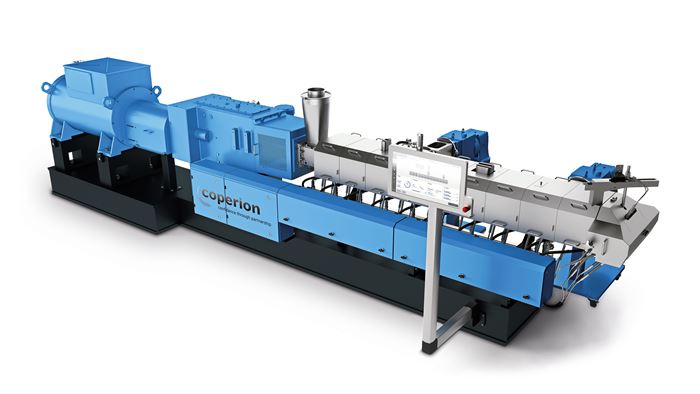

In compounding, various materials (polymers, additives, etc.) are mixed and melted—generally in an extruder of some type—then pelletized. Most compounding extruders purchased nowadays are of the twin-screw corotating/intermeshing variety, though counterrotating twins are used for some applications. Compounding extrusion lines are typically equipped with gravimetric feeding systems that dose materials into the extruders at very specific rates. In certain applications, extruders are equipped with vent ports that pull unwanted moisture and other volatiles from the polymer stream.

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Compounding: Essential Reading

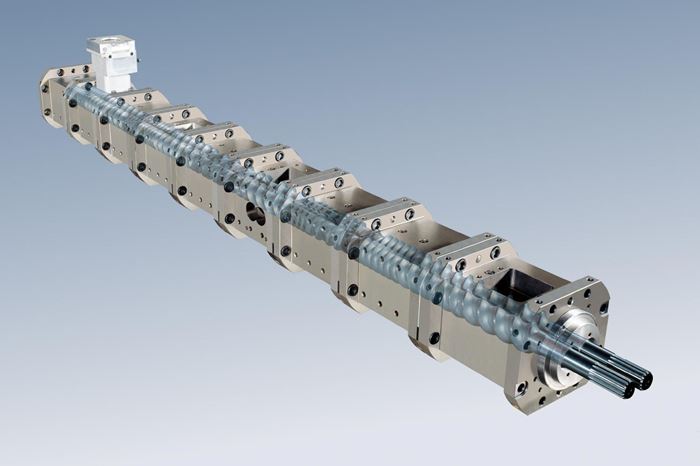

How to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

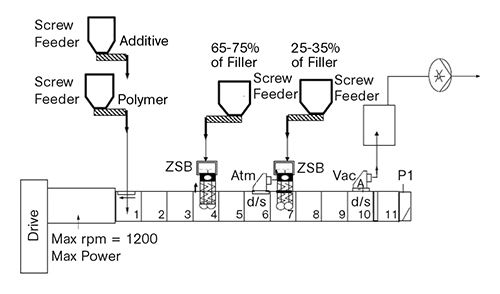

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

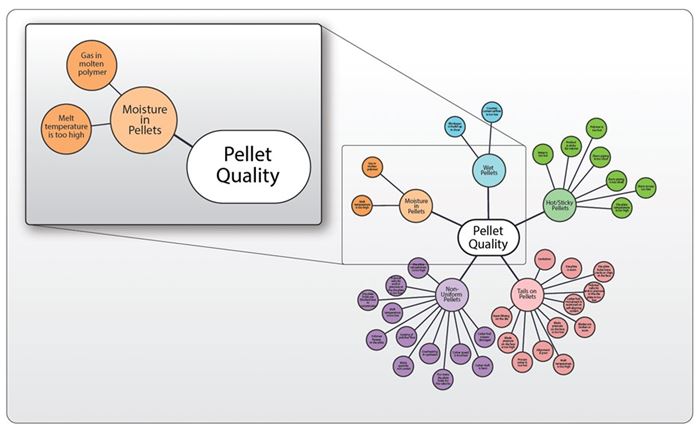

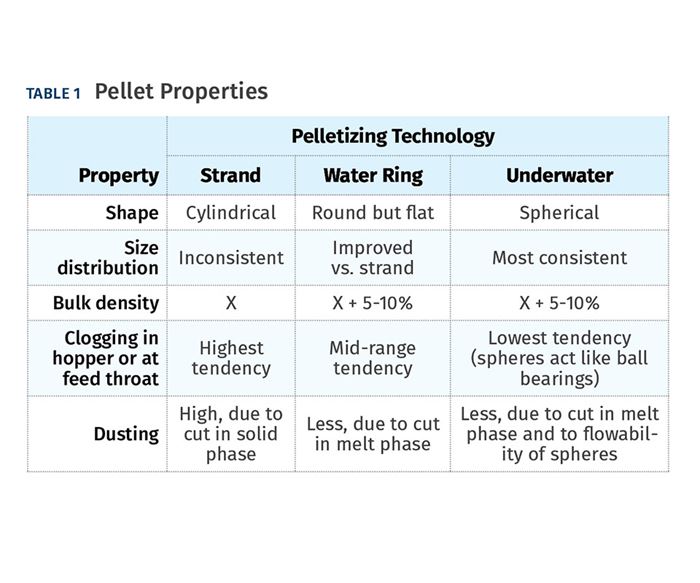

The Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

Use These Twin-Screw ‘Tools’ to Improve Quality of Your Color Pigment Dispersions

A twin-screw compounding extruder is a single piece of equipment divided into distinct unit operations. Thinking of each unit operation as part of a toolbox can help determine what can be added or improved to process best-quality color masterbatches.

FAQ: Compounding

How can I optimize my twin-screw compounding process?

We identify problems in compounding as “chronic” if the results are the same every time a particular formulation is run. For these problems, the treatment requires redesigning the screw configuration or modifying the compounding process. This is the only way to cure such problems.

Many new players have emerged in the biopolymer space with new materials and many new formulations. Co-rotating twin-screw extruders provide excellent material mixing capabilities for all polymers, including biopolymers. You should consider your machinery supplier as a development partner to achieve your goals in the areas of melt and mix quality, production rates, and other parameters, regardless of formulation. Make sure your machinery supplier has the facilities and the know-how to help you test material formulations and improve your processes.

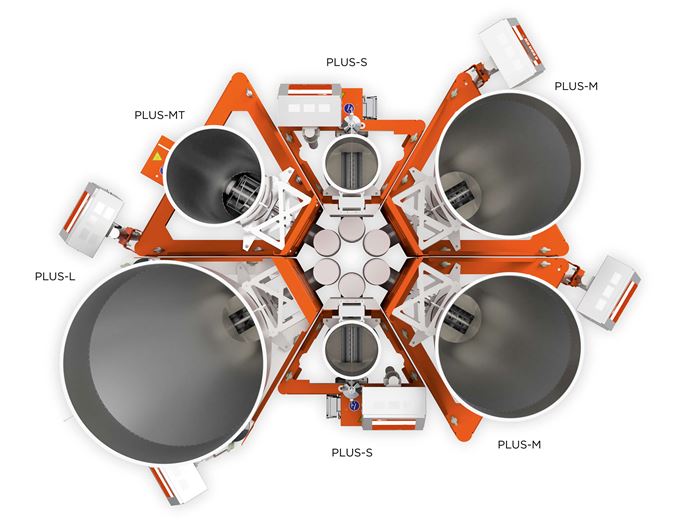

Pelletizers are essential components in resin manufacture, compounding, masterbatch production, and recycling. A high-volume system that is appropriate for a polymerization plant will be very different from one that suits the needs of a toll compounder. One that can produce micropellets for use in masterbatch may not be the best choice for processing post-consumer regrind. Here are some different types of pelletizers.

- UNDERWATER PELLETIZERS

- WATERRING PELLETIZERS

- STRAND PELLETIZERS

Compounding Suppliers

Narrow by Compounding Category

- Blenders (non-intensive)

- Intensive Fluxing (melting) Mixers

- Intensive Nonfluxing Mixers

- Liquid Mixers

- Motionless Mixers

- Roll Mills

- Tumblers

- Curtain Coaters

- Knife Coaters

- Plasma Coating Systems

- Roll Coaters

- Slot Orifice Coaters

- Coextrusion Dies, Feedblocks

- Extrusion Dies

- Multiple-screw Extruders

- Plastic Lumber Extrusion/Molding Systems

- Ram Extruders

- Rotary Screwless Extruders

- Single-screw Extruders

- Film Take-off Systems

- Monofilament/Multifilament Take-Off Systems

- Profiles, Tubing, Hose Take-off Systems

- Pipe Take-off Systems

- Sheet Take-off Systems

- Wire and Cable Take-off Systems

- Film, Sheet, Coated Web Thickness Measuring Equipment

- Pipe Thickness Measuring Equipment

- Profiles, Tubing, Wire Thickness Measuring Equipment

- Web Brakes, Clutches, Chucks

- Web Cleaning Equipment

- Web Guides, Edge Detectors

- Web Inspection Systems

- Web Slitter/Rewinders

- Web Slitters

- Web Tension Controls

- Web Winders, Unwinds, Rewinds

- Automation/Systems Integration

- Barrier Surface Treatment

- Business Services for Plastics (Finance, Insurance, Leasing)

- Consultants - Design, Manufacturing, Purchasing

- Custom Compounding, Formulating--Thermoplastics

- Custom Decorating/Finishing Services

- Custom Machine Builders

- Custom Size-reduction (Grinding) Services

- Environmental Monitoring and Analysis

- Equipment Cleaning Services

- Hard Facing, Surface Treating of Tooling, Equipment

- Hydraulic Oil Filtering/Reclaim Service

- Machine Alignment Services

- Machine Installation Services

- Machine Maintenance Services

- Machinery Rebuilding

- Materials Testing Services

- Mold Texturing, Tool Engraving

- Mold/Tooling Design Services

- Mold/Tooling Simulation and Analysis Services

- Part/Mold Inspection or Digitizing

- Plastics Trade Shows/Conferences

- Prototyping Services

- Publishers of Plastics Information (Books, Reports, CDs)

- R&D, Training Institutes

- Radiation Processing Services

- Rebuilt Motors and Drives

- Rebuilt Screws or Barrels

- Recycling--Purchasing Scrap or Waste Plastics

- Scanning & Metrology Services

- Shipping & Logistics

- Technical and Trade Associations

- Training Programs in Plastics

- Used Machinery

- Used Molds