Plastics are deployed in every day products in a number of end markets, including automotive, construction and infrastructure, consumer products, electronics, medical and packaging.

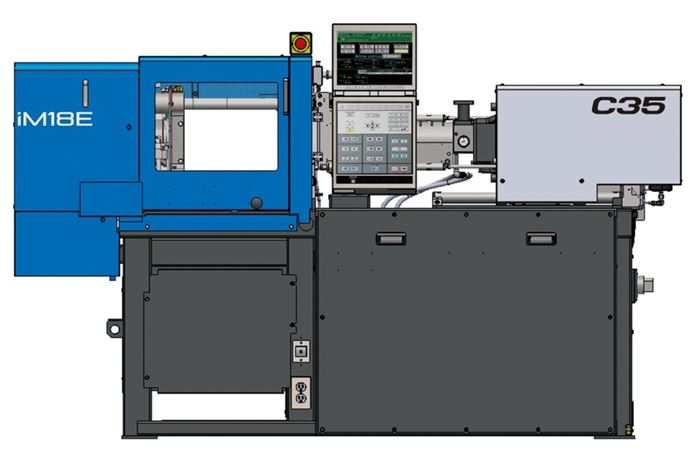

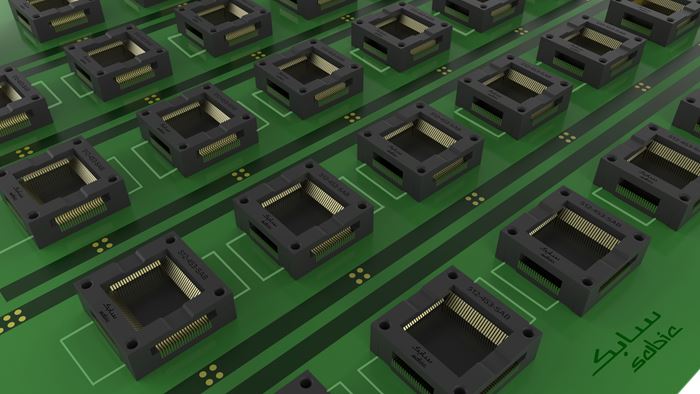

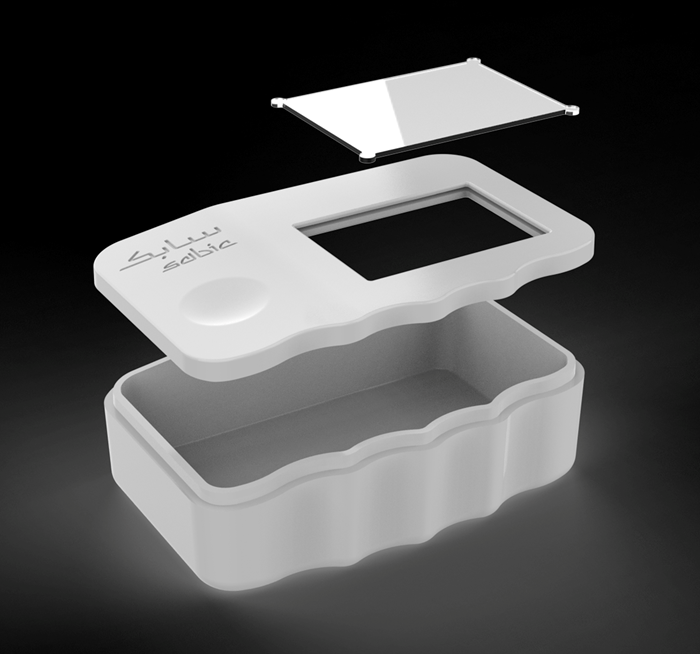

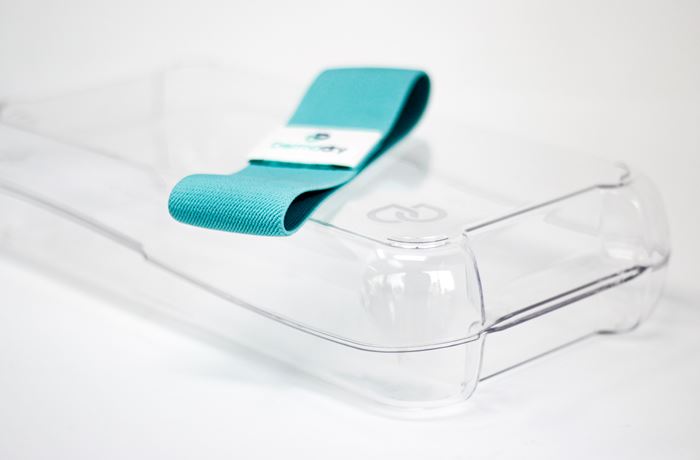

Use Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

End Markets: Essential Reading

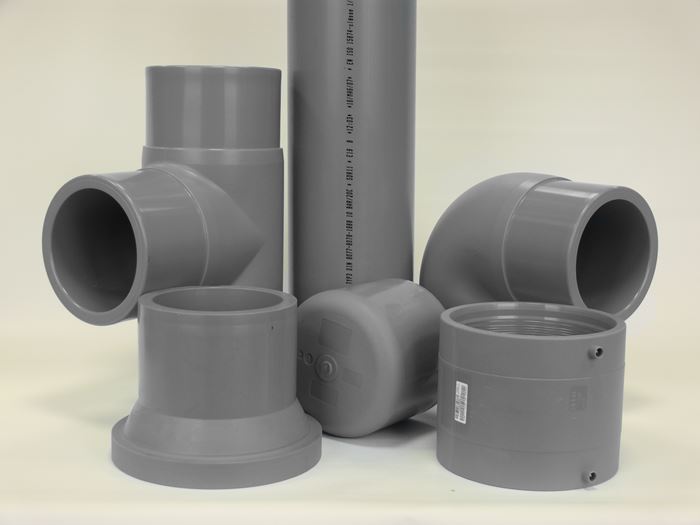

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

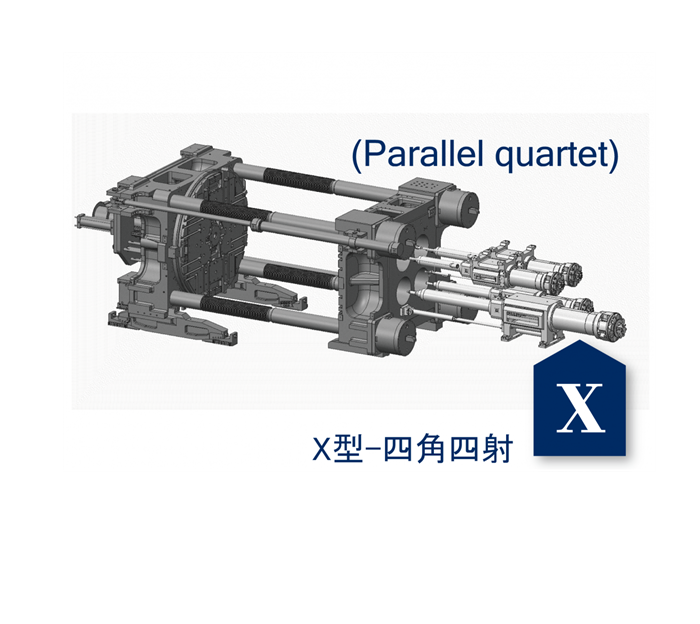

Solve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

Formulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

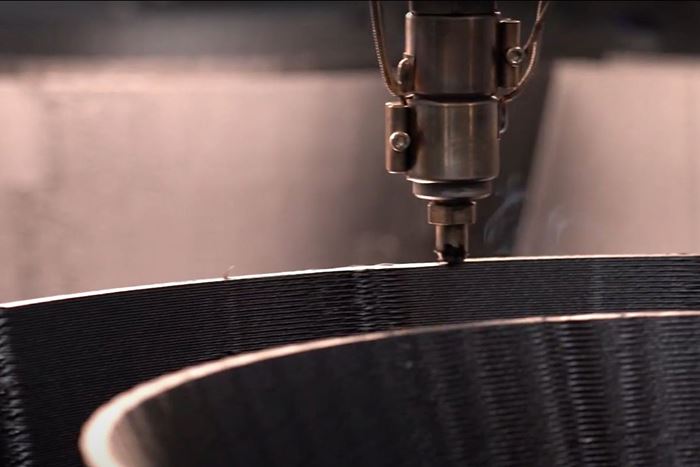

How to Know the True Value of Conformally Cooled Injection Molds

What’s the return on investing in a new mold with conformal cooling to boost productivity? Will it pay for itself? How soon? Here’s a case study on how to answer those questions.

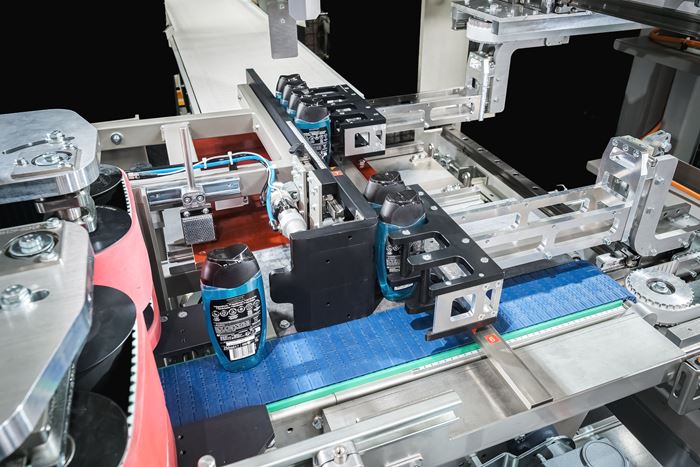

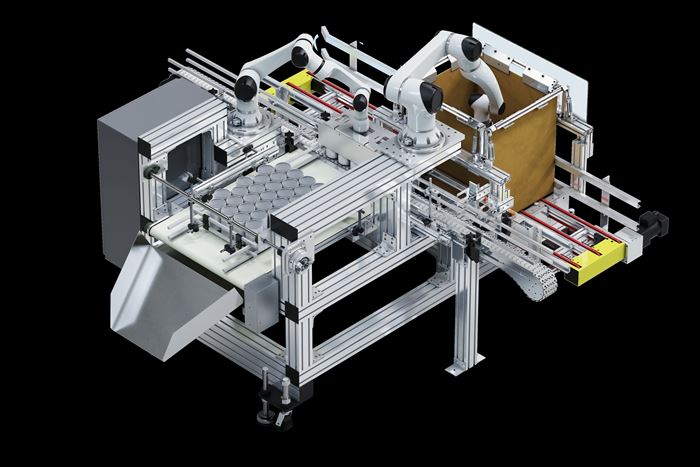

What to Look for in High-Speed Automation for Pipette Production

Automation is a must have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floorspace consumption and payback period.