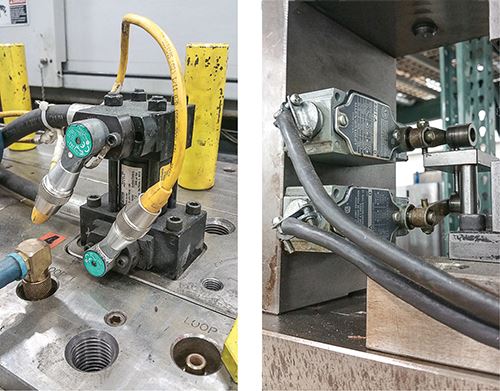

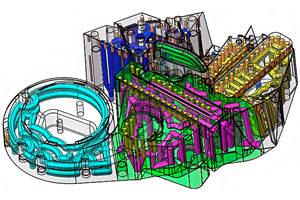

The Impact of Hydraulics on Tool Design, Practical Uses -- Part 2 of 2

Here are more tips on using hydraulically actuated devices on your tools.

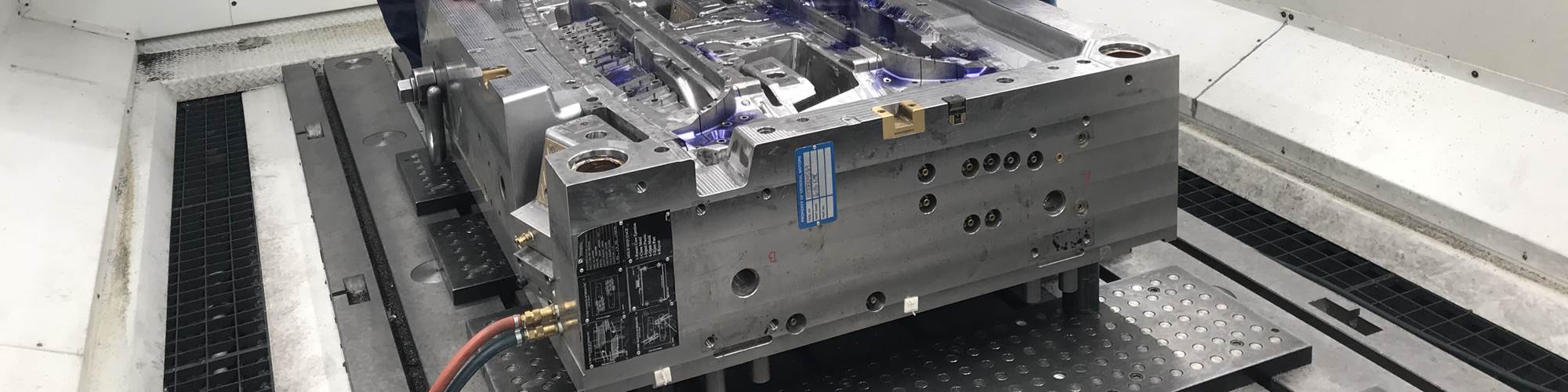

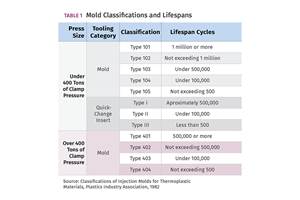

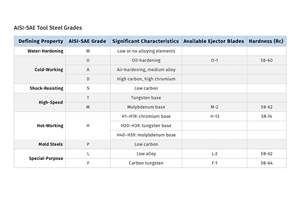

How to Select the Right Tool Steel for Mold Cavities

With cavity steel or alloy selection there are many variables that can dictate the best option.

#bestpractices

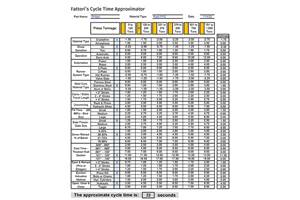

How Do You Estimate Cycle Time?

Molders price jobs based on estimated press time, and that is where you can either be very profitable or lose your shirt. But there’s a new, free resource to help you out.

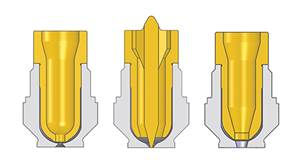

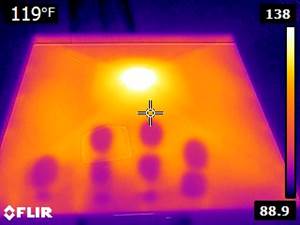

Hot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

#processingtips #bestpractices