The Effects of Time on Polymers

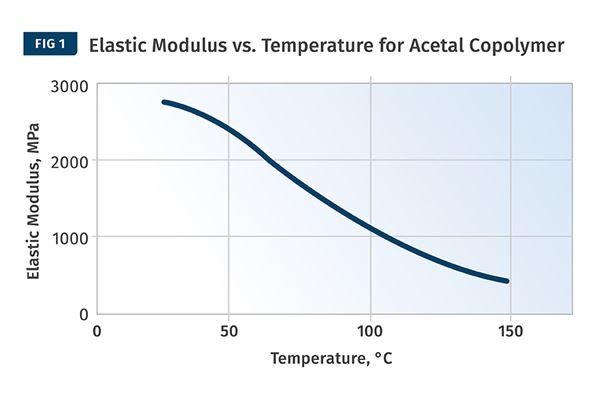

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Michael Sepe

, Michael P. Sepe LLC

The Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

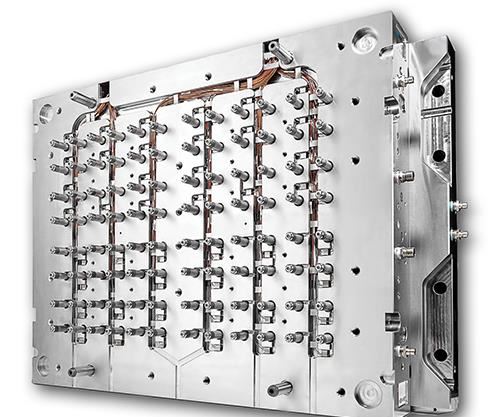

Hot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

How to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

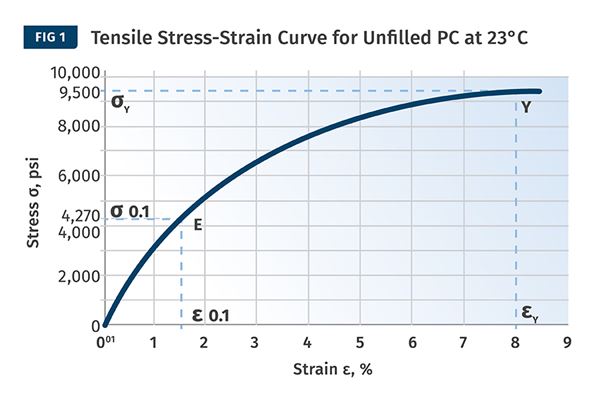

The Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Understanding Intensification Ratio

A first step in taking the “art” out of molding.